Introduction: Shot Blasting vs Sandblasting – What’s the Difference?

In the world of industrial surface preparation, shot blasting and sandblasting are two powerful methods used to clean, strengthen, and prepare metal surfaces before coating, painting, or welding. While both processes are forms of abrasive blasting, the benefits of shot blasting over sandblasting are increasingly being recognized across heavy industries, automotive manufacturing, construction, shipbuilding, and foundries.

At Mahadev Engineering, a leading manufacturer of industrial shot blasting machines and sand blasting equipment, we often guide clients on choosing the most efficient method. In this blog, we dive deep into the top 5 advantages of using shot blasting instead of sandblasting for industrial applications.

- Superior Surface Profile and Finish Quality

One of the key benefits of shot blasting over sandblasting is the better surface profile it delivers. Shot blasting uses metallic abrasive media (such as steel shots or grits) that strike the surface with controlled velocity and impact.

Why This Matters:

- Creates a uniform, rough texture ideal for coating adhesion.

- Enhances the bonding strength of primers, epoxy, and powder coatings.

- Ideal for steel surface preparation, casting cleaning, and weld seam preparation.

Dust-Free and Environmentally Safer Process

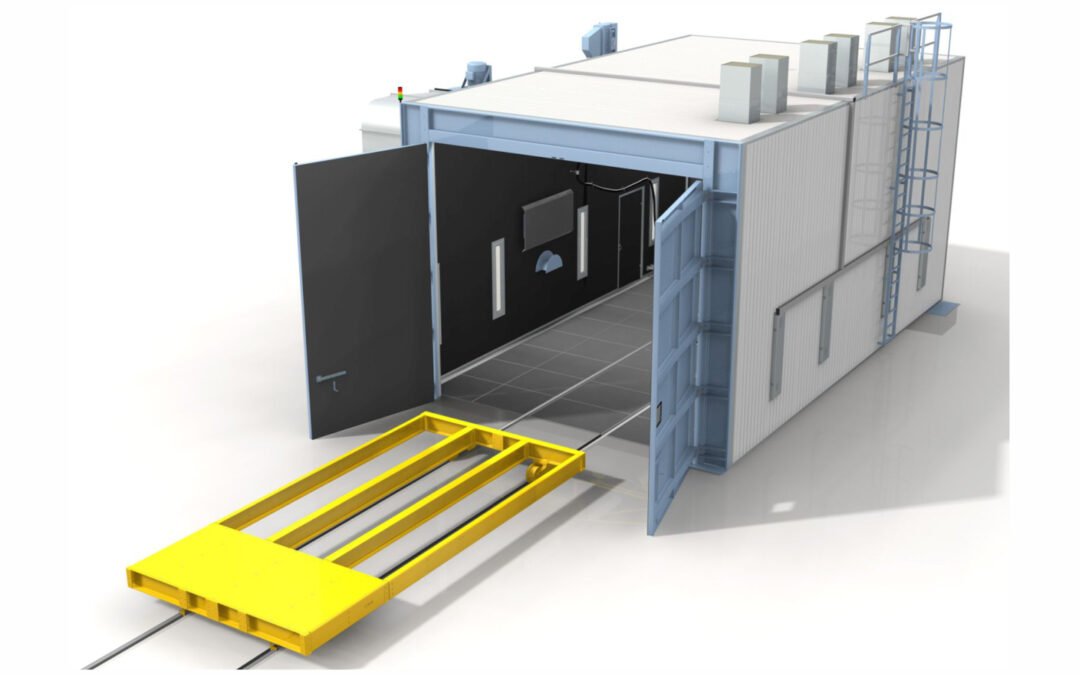

Unlike sandblasting, which generates high volumes of silica dust and airborne particles, shot blasting machines are typically dust-free or self-contained systems with built-in dust collectors. This makes shot blasting environmentally friendly and safer for operators.

Environmental & Safety Advantages:

- No silica-related health hazards (like silicosis).

- Cleaner workspace with integrated dust collector systems.

- Ideal for indoor industrial applications and closed-loop setups.

- Higher Cleaning Efficiency and Speed

Shot blasting is automated and faster, making it suitable for high-volume production lines. Industrial shot blasting machines can handle large workpieces with consistent cleaning power, removing rust, scale, old paint, and contaminants in a single pass.

Why Industries Prefer This:

- Faster turnaround times in manufacturing.

- Consistent and repeatable results.

- Minimizes manual labor and downtime.

- Long-Term Cost-Effectiveness

Though initial investment in shot blasting equipment might be higher than sandblasting setups, the long-term ROI (Return on Investment) is far superior.

Reasons Why Shot Blasting is Economical:

- Reusable abrasive media reduces recurring costs.

- Less downtime due to robust machine performance.

- Low operational cost with minimal waste.

- Enhanced Surface Strength & Durability

Shot blasting not only cleans but also strengthens the surface by inducing compressive stress, which improves fatigue resistance. This is a major reason why industries like automotive, aerospace, and steel fabrication choose shot blasting over sandblasting.

Material Strength Benefits:

- Surface hardening increases fatigue life.

- Reduces risk of stress corrosion cracking.

- Prepares surfaces for high-performance applications.

Conclusion: Why Choose Shot Blasting for Industrial Surface Preparation

While both shot blasting and sandblasting have their place in industrial surface cleaning, the advantages of shot blasting in terms of efficiency, safety, cost-effectiveness, and surface quality make it the superior choice for heavy-duty applications.

At Mahadev Engineering, we specialize in manufacturing world-class shot blasting machines, sand blasting machines, and dust collector systems. With decades of experience in serving industries like automotive, construction, foundries, and steel fabrication, we help our clients choose the most effective surface preparation solutions.